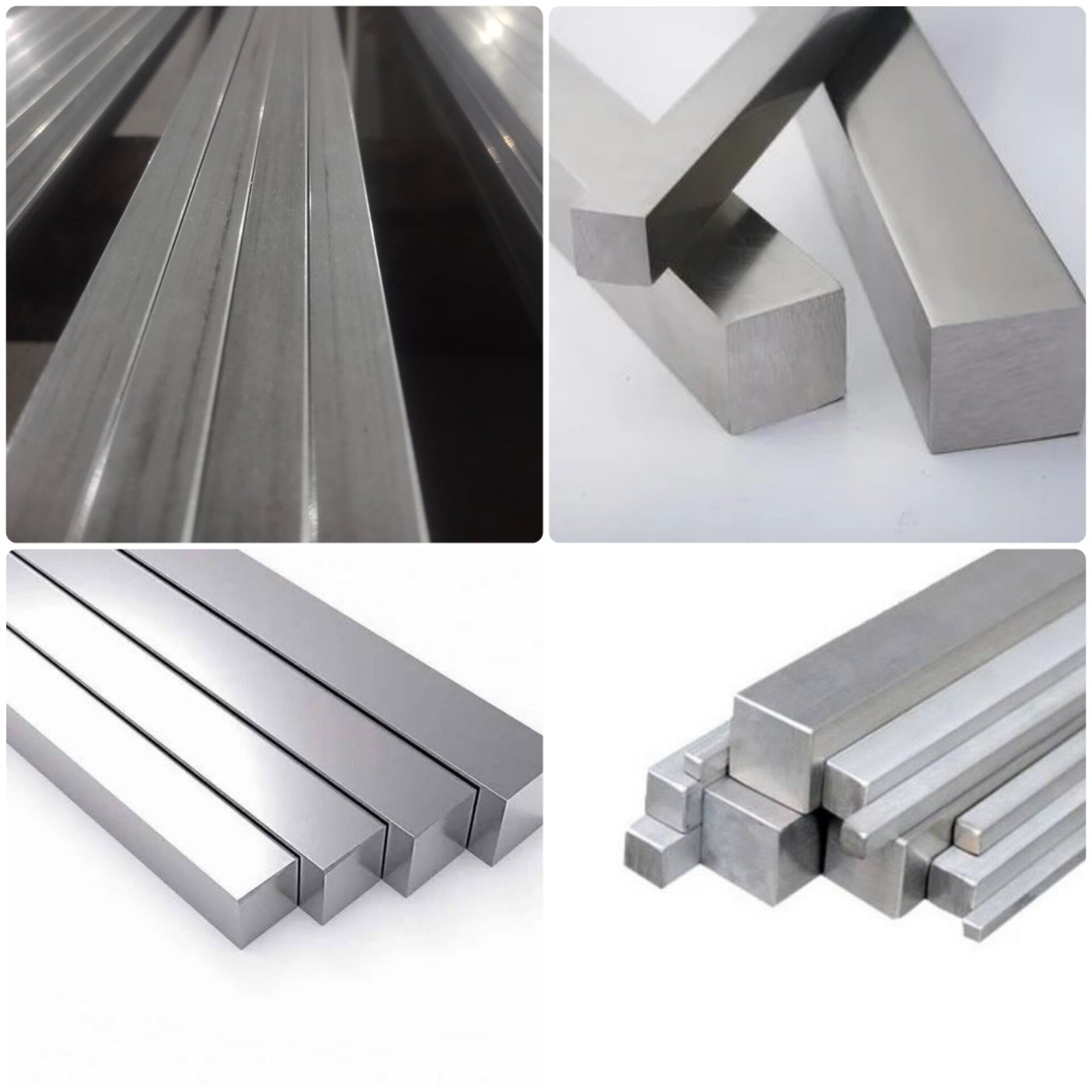

Square Bars Manufacturer

Chandan Bright Bars is a premier manufacturer of high-quality square bars, serving a wide array of industries with precision-engineered products. Our square bars are available in sizes ranging from 3 mm x 3 mm to 65 mm x 65 mm, accommodating a broad spectrum of applications from construction to machinery manufacturing. We offer these bars in standard lengths of 3 meters, 4 meters, and 6 meters, and can also provide exact lengths tailored to specific customer requirements.

Square bars from CHANDAN are known for their robust quality and exceptional dimensional accuracy. They are manufactured using advanced techniques to ensure consistent performance and durability. Whether used in Structural Frameworks, Fasteners, Shafts, Machining Applications, Components, Hardware, Industrial machines, or custom fabrication projects, our square bars deliver reliable strength and versatility. At Chandan Bright Bars Pvt Ltd, our dedication to quality and customization ensures that each product meets the stringent demands of our customers, providing them with the best possible solutions for their needs.

Square Bars Specifications

| Size range | 3mm x 3mm TO 65mm x 65mm |

| Size Tolerances | H6, h7, h8,h9, h10, h11,h12,J5, J6, J7, k12, k13, A-484, EN-10060, DIN-1013 etc (Special tolerance as per customer requirements) |

| Length | 3 MTRS / 4 MTRS / 6 MTRS (OR Exact length as per customer requirements) |

| Crack Test | Ultrasonic Test (UT), Magnetic Particle Inspection (MPI)&Non Destructive Test (NDT) |

| Ultrasonic Test | 100% tested through Digital Ultrasonic Flaw Detector, as per ASTM A-388, EN 10308 (class 1 to 4), API 6A/ISO 10423:2003-PSL 3, SEP 1920:1984 (class A, B, C), MIL STD 2154 |

| Surface Finish Type | Hot Rolled, Hot Rolled Annealed, Hot Rolled Annealed Pickled, Bright Square Bars, Aluminium Milky Finish, Lime finish, Soap Coated, Powder Coated, Electro Polished, Mirror Finish (Special surface finish as per customer requirements) |

| Hardness | Normal, Normal Soft, Extra Soft, Free Machinable Quality, Full Hard, Half Hard Etc ( As per customer requirements) |

| Heat Treatment | Annealed, Solution Annealed, Quenched & Tempered (QT), Double Ageing/Double Tempering, Special hardness as per customer requirements |

| GRADES | SS 201, 202, 202CU, 204, 204CU, 301, 303, 303CU, 304, 304L, 304H, 308, 309, 309s,310, 310s, 316, 316L, 316ti, 317, 317L, 318, 321, 340, 410, 416, 420, 430, 430L, 430LNB, 430F,431, 440,440C,17-4ph, Duplex 2205 Etc (ALL GRADES OF MILD STEEL, CARBON STEEL, ALLOY STEEL) & Other metal alloys |